The ROCIS Air Handler - High MERV Filter Inquiry

Continuous Filtration

Why run your air handler fan continuously?

If you already have a filter built into your heating and cooling system you might be tempted to just let it filter the air whenever the HVAC kicks in. But studies have shown that over the course of the year, residential heating and air condition systems simply do not operate long enough to effectively filter the air. All told, you might only be filtering your air 15% of the time. Setting up your system to filter the air continuously can make a huge difference in air quality. However, many HVAC systems may not currently be well-equipped to handle continuous operation without modification. Read on to learn about retrofitting your air handler.

Modifications for continuous filtration

This 10-minute video, assembled from presentations by ROCIS team members, provides an overview of what it takes to add continuous, high-performance filtration to the system without breaking the bank.

The ROCIS Air Handler Intervention

If you’re thinking about updating your air handler system to operate the fan 24/7, this inquiry is an essential first step. Certain conditions must be met, and the appropriate intervention will vary depending on the performance of the individual HVAC system. The ROCIS air handler unit (AHU) checklist enables the identification of deficiencies in the current system and improvements that need to be made.

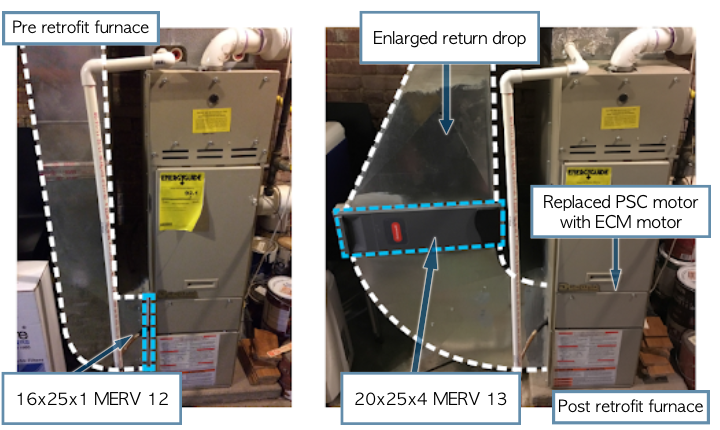

Retrofitted Furnace Showing Filter in Place

This furnace belongs to Ryan Coon, one of our LCMP participants who was featured in the Clean Air Chronicles.

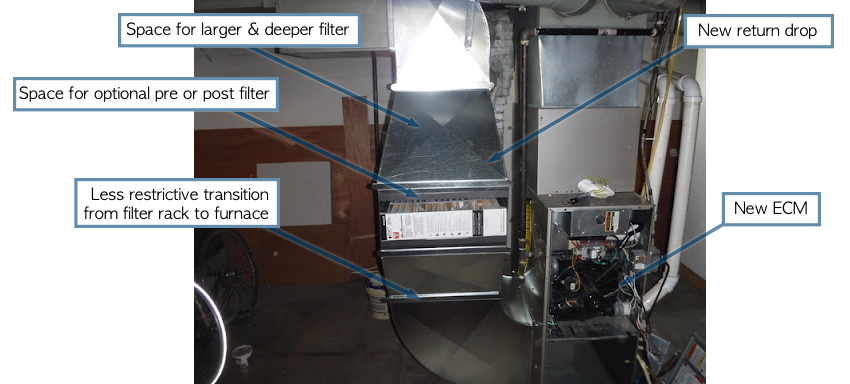

Note: The return drop modification would be done either as a correction to an existing system or as an enhancement to the installation of a new HVAC system installation. This diagram shows a modification that overcomes two of our most frequently identified barriers to using an air handler to effectively reduce particles: (1) restrictions to the return side of the duct system in the return drop and (2) restrictions to airflow caused by an existing filter.

The ROCIS Air Handler Inquiry has focused exclusively on HVAC systems in southwestern PA. Forced air system design varies with different house types. Most of our experience is focused on homes with HVAC systems located in the basement.

ROCIS 24/7 Air Handler Checklist: Optimizing Residential Air Handlers for 24/7 Filtration

Follow this checklist to identify deficiencies in the current system and determine which improvements need to be made.

The appropriate intervention varies according to the performance of the individual HVAC system.

When using a typical residential air handler, the following conditions should be met in order to run the fan continuously:

The air flow is adjusted to 300–400 cfm in the continuous mode, while air flow is also in the optimum flow rate for both heating and cooling.

The TESP (total external static pressure) is lower than the maximum specified on the manufacturer’s nameplate.

A MERV 13 (usually 4”) high-quality air filter is fitted within a filter slot that provides a good seal to minimize bypass. (The fat, high-quality filter will not be as subject to clogging and will not offer as much resistance to airflow.)

The duct system is primarily within the conditioned space of the building, with little evidence of duct leakage to the outside.

The primary actions we take to achieve the conditions in the checklist:

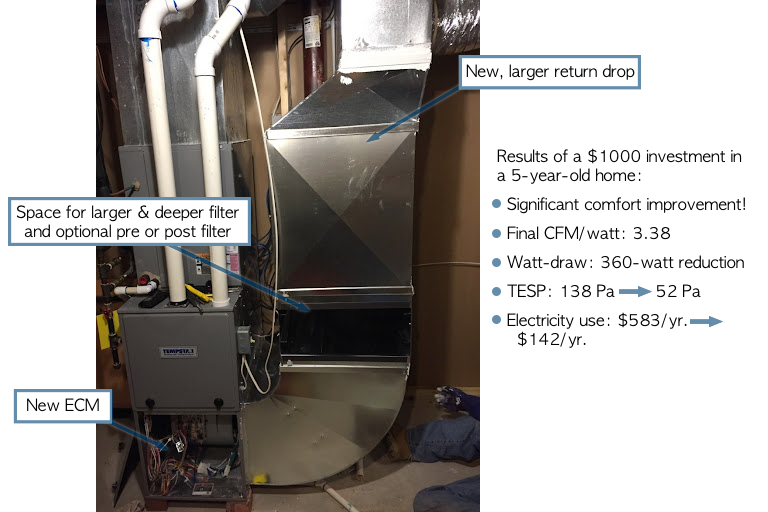

Change out ECM to achieve lower watt-draw

Caveat: If the TESP is high, the ECM may perform worse in terms of watt-draw than the original PSC motor. Therefore, the ECM change-out is only advisable if the static pressure of the system is lower than the nameplate rating—and also if we can use a fat filter with minimal chance of becoming clogged.

Replace the return drop with a larger cross-sectional area return that includes a horizontal filter slot for a larger filter, as well as a second filter.

Over 50% of the systems checked have restrictions in the return side ductwork. In many cases, a larger and better design for airflow in the return drop can improve the static pressure. In addition, by moving the filter slot to a horizontal position and making it larger and deeper in dimension (usually 20″ x 25″ instead of 16″ x 25″), the static pressure over the filter is reduced. The 90° angle at the bottom of the vertical duct is fabricated with a curve on both the throat and the heel to minimize static at this location.

Adjust the fan setting for optimum airflow for the continuous, heating, and cooling modes.

In most cases, the fan is wired to default to continuous mode. This can also be controlled at the thermostat.An added benefit of this intervention is that with lower face velocity over a larger filter, the filter will more effectively remove small particles.

Intervention items under consideration:

-

- Controlling the air handler run-time in response to air quality through a smart thermostat and feedback regarding air quality.

- Monitoring the system’s performance in terms of resistance over the filter (and possibly watt-draw) to determine when the filter should be replaced.

- Providing for charcoal filtration in an additional filter slot in order to reduce other air contaminants in addition to particles.

- Other control options in response to occupancy.

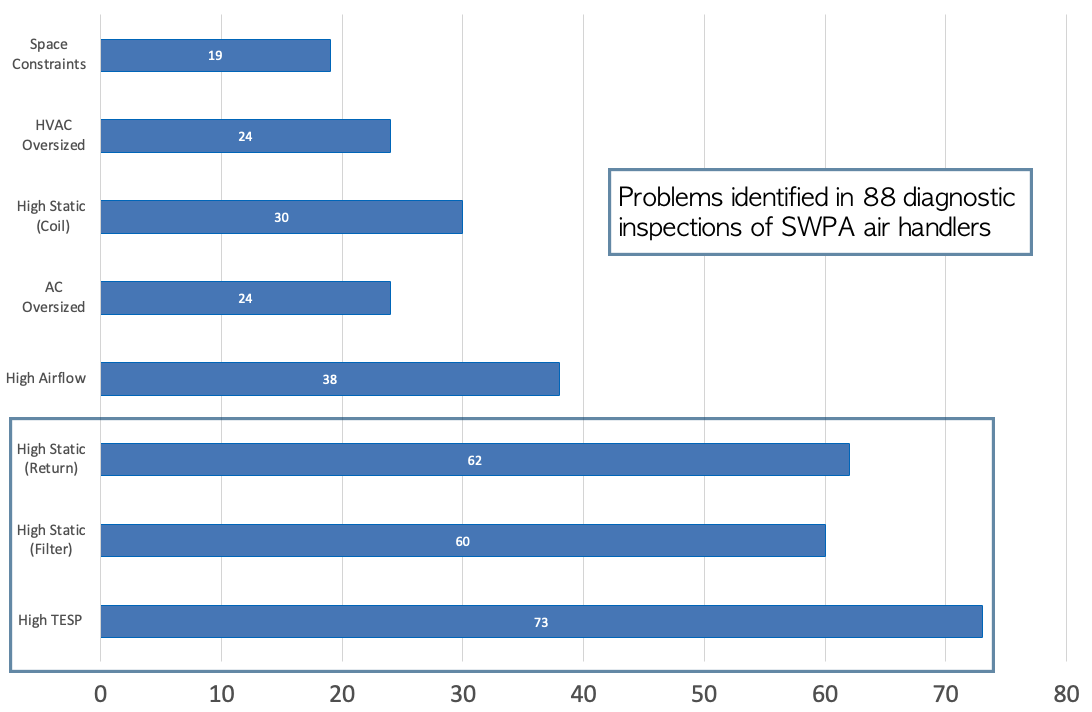

Air Handler Inquiry Findings

Here’s what we found after doing more than eighty feasibility inspections for folks hoping to modify existing residential HVAC systems for particle filtration. The graph below summarizes the barriers to modification.

NOTES:

In the chart above, “AC Oversized” and “HVAC Oversized” are in reference to duct size, not the home. Many more systems than reflected here are oversized when compared to the home’s heating and cooling loads.

Most of these HVAC systems were located in a basement with the ducts located within the basement and the home’s conditioned space.

The ROCIS Air Handler Diagnostic Visit

The purpose of this visit is to clarify whether the furnace and/or central air conditioner’s air handler filter can be a viable tool to reduce indoor particles in the homes of participants in the ROCIS Low Cost Monitoring Project (LCMP). We recommend having it done regardless of whether or not LCMP participants are using a high-performance filter.

The visit usually takes 2 to 2.5 hours. At the time of the diagnostic visit, participants find out the electrical cost of operating their air handler. Afterward, they receive a written report with a summary of the findings and recommendations.

Depending on the system, it is possible that modifications could be made at the time of the diagnostic visit. For example, during the more than 60 diagnostic checks that we have conducted, over 50% of the time we have made improvements to optimize the blower speed during the visit—resulting in improved comfort, performance, and energy use.

However, there are only a few cases in which we have recommended that the air handler (as is) be run continuously to provide better filtration. With the right modifications, it appears to be a very effective intervention. Nonetheless, very few air handlers are set up to provide that option without adverse consequences such as very high electricity use ($60+/month) or shortening the life of HVAC equipment.

We have not seen a clear reduction in particles when LCMP participants have a high-performance filter and operate their system in auto mode, which only runs the fan when there is a call for heating or cooling.

Using tests to check air handler performance under different operating conditions (heat, air conditioning, and continuous fan), the diagnostic visit determines the following:

1. Energy use at different blower speed settings

2. Total external static pressure (TESP) of the entire system as well as for each HVAC system component (return duct, filter, supply duct, and over the coil)

3. Predicted or measured airflow in comparison to the system’s recommendation for optimal performance

4. Potential to change the blower speed for energy savings and/or reduce (if appropriate) the total external static pressure (TESP)

5. Potential for a smart thermostat to modify the operation of the air handler

6. Whether or not:

a) a lower or higher MERV filter and /or deeper filter is an appropriate system upgrade

b) an ECM replacement is a viable option

c) duct modifications are a viable option

In addition, we measure the airtightness of the home or workplace with a blower door and perform a visual inspection of the duct system.

This furnace went through the ROCIS air handler inquiry and intervention. Check out the results.

Additional Info on the ROCIS Air Handler Intervention

2022 National Home Performance™ Conference

April 11–14, 2022

Particle Filtration With Central Air Handlers: Folly or Opportunity?

Linda Wigington & Rhett Major

2020 Home Performance™ Regional Education Series: New England

November 13, 2020

Air Handlers: Folly or Opportunity?

Rhett Major & Linda Wigington

Linda Wigington interviewed at the 2017 National Home Performance Conference

March 19-22, 2017

Green HVACR Magazine, Issue #5, featuring ROCIS: “Improving A Home’s IAQ”

Read the article online: Improving a Home’s IAQ

Download the article as a PDF: Improving a Home’s IAQ (PDF)